HP production shift to dodge China tariffs

HP’s production shift to dodge China tariffs involves relocating manufacturing to enhance efficiency, reduce costs, ensure sustainability, and mitigate risks associated with geopolitical tensions.

HP production shift to dodge China tariffs is a significant move in the tech industry. This change not only aims to minimize costs but also reflects a broader trend among businesses responding to trade dynamics. How does this impact you and the tech landscape?

Understanding the impact of China tariffs

Advertisements

Understanding the impact of China tariffs is crucial for businesses like HP. These tariffs affect pricing and supply chains, making it essential to analyze their implications carefully.

When tariffs increase, companies often face higher costs for imported goods. This can lead to several outcomes, including price hikes for consumers. Moreover, businesses might need to find ways to adjust their operations to maintain profit margins.

The Key Effects of Tariffs

There are several significant effects that tariffs can have on the tech industry:

- Increased costs for manufacturers and consumers

- Shifts in supply chain strategies

- Potential relocation of production facilities

Furthermore, tariffs can influence market competition. Companies that rely heavily on imported goods may struggle, while domestic manufacturers can benefit from reduced competition.

Long-term Industry Changes

Over time, the impact of tariffs can reshape entire industries. Companies like HP might explore new markets and adapt their business strategies to stay afloat.

This shift can also push for innovation within the industry, encouraging firms to develop new technologies that lessen dependency on specific regions. In this sense, tariffs can serve as a catalyst for change.

Ultimately, understanding these dynamics allows companies to make informed decisions. As HP navigates these challenges, being aware of the tariffs’ effects is key to their long-term success.

HP’s strategic relocation decisions

HP’s strategic relocation decisions are pivotal in responding to changing economic conditions. These decisions help the company adapt to challenges like new tariffs imposed on imports from China.

Relocation can mean moving production facilities to countries with lower costs or more favorable trade agreements. This shift not only aims to reduce expenses but also enhances operational efficiency.

Factors Influencing Relocation

Several factors drive HP’s decision to relocate:

- Cost savings on production

- Access to skilled labor

- Proximity to target markets

The search for lower labor costs is a significant motivator. Countries with competitive wage structures can provide HP with the necessary savings to stay competitive in the tech market.

Benefits of Strategic Relocation

Strategic relocation brings various advantages. For HP, these benefits include:

- Improved supply chain resilience

- Faster response to market demands

- Reduced vulnerability to tariffs and trade barriers

By relocating, HP can also mitigate risks associated with dependency on a single country for production. This adaptability ensures that the company can thrive in a volatile global marketplace.

Moreover, HP’s choices reflect a deeper trend in the tech industry. Many companies aim to create more resilient operations by diversifying their geographical footprints. As they navigate these changes, understanding the rationale behind these moves is crucial for stakeholders.

Benefits of shifting production locations

The benefits of shifting production locations are significant for companies like HP. By relocating production, businesses can adapt to the changing global market and maximize their efficiency.

One major advantage is cost savings. Companies often find that moving to countries with lower labor costs can dramatically reduce their overall expenses. This allows firms to offer competitive prices to consumers while maintaining margins.

Improved Operational Flexibility

Shifting production also enhances operational flexibility. With resources spread over various locations, companies can respond quickly to market demands. For example, if a facility in one country faces disruptions, production can be adjusted from another site.

Access to New Markets

Another key benefit is access to new markets. By relocating, companies like HP can produce goods closer to where consumers are, which can lead to faster delivery times. This strategy can significantly improve customer satisfaction.

- Shorter shipping times and reduced logistics costs

- Better understanding of local consumer preferences

- Enhanced ability to customize products for local markets

Additionally, shifting production locations enables companies to mitigate risks associated with political or economic instability in any single country. This diversification is crucial for long-term sustainability.

Furthermore, as companies explore new locations, they may discover innovative practices and technologies that improve production methods. This continuous improvement drives better products and services.

Challenges faced during the transition

Companies like HP face various challenges during the transition of production locations. This process requires extensive planning and execution to ensure smooth operations.

One of the most significant challenges is managing the logistics of moving equipment and personnel. Companies must carefully coordinate these efforts to minimize downtime and maintain productivity.

Workforce Management

Another challenge is workforce management. Relocating production may require hiring new employees or retraining existing staff. A successful transition involves ensuring that the workforce is skilled and ready for new processes.

Supply Chain Disruptions

Supply chain disruptions are also common during transitions. Companies may experience delays or interruptions while shifting suppliers and establishing new contracts. This can impact inventory levels and delivery times.

- Difficulty in finding reliable suppliers in the new location

- Potential increases in shipping costs

- Unforeseen delays in equipment installation

Moreover, navigating the regulatory requirements in a new country can be complex. Compliance with local laws and regulations is critical for a successful operation. Companies must be aware of different labor laws, environmental regulations, and import/export duties.

Additionally, maintaining the quality of products during the transition can be challenging. Companies need to ensure that quality control processes are in place to avoid defects or inconsistencies. This can require extra training and oversight, adding to the complexity of the transition.

Future of HP’s manufacturing strategy

The future of HP’s manufacturing strategy is focused on adaptability and innovation. As global markets evolve, HP is positioned to leverage new technologies and trends to remain competitive.

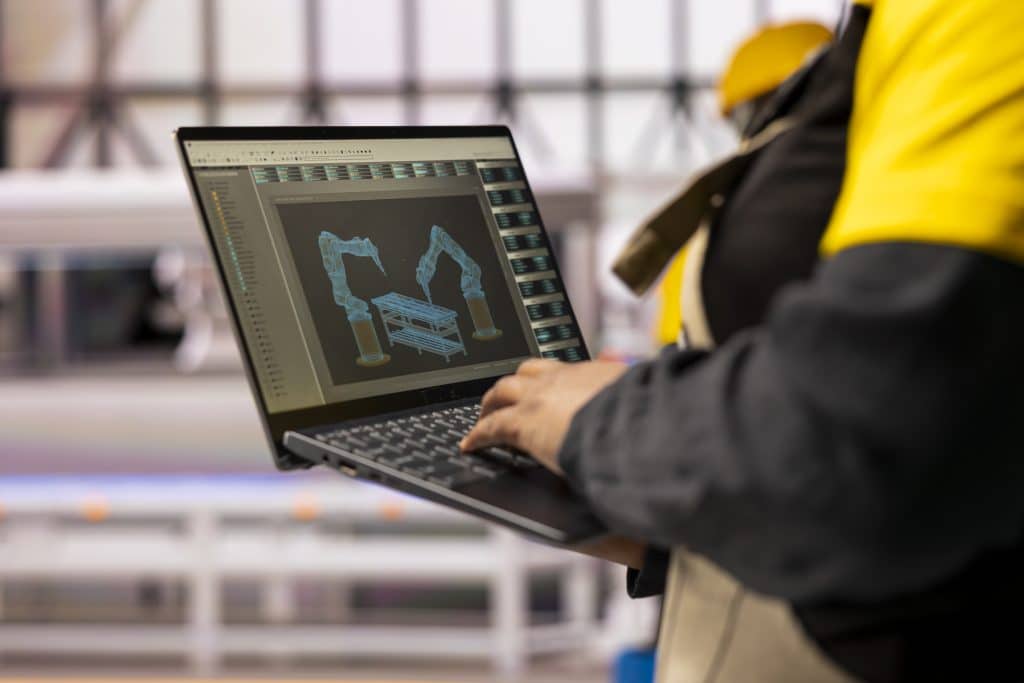

One key aspect is the integration of advanced automation in manufacturing processes. By utilizing robotics and AI, HP can increase efficiency and reduce production costs. This approach allows for faster turnaround times and higher quality products.

Emphasis on Sustainability

Another significant focus for HP is sustainability. The company aims to create environmentally friendly products and reduce waste during manufacturing. This could involve using recycled materials and minimizing energy consumption.

Diversified Manufacturing Locations

HP is also likely to continue diversifying its manufacturing locations. This strategy helps mitigate risks associated with geopolitical tensions and supply chain disruptions. By spreading operations across different regions, the company can respond more effectively to challenges:

- Access to local markets and suppliers

- Enhanced flexibility in production

- Better compliance with regional regulations

Moreover, HP is expected to invest in research and development to explore new manufacturing technologies. This could lead to innovations that further improve their production capabilities. Engaging in partnerships with tech startups and other companies can also drive innovation.

Additionally, HP may adapt its product lines to meet changing consumer preferences. This involves being responsive to trends such as remote work and the growing demand for home office equipment.

Conclusion: The Broader Implications of HP’s Move

HP’s strategic production shift to dodge China tariffs underscores a defining moment for the global tech supply chain. This move highlights how major manufacturers are rethinking their operational footprints to remain competitive in a rapidly evolving geopolitical and economic environment. By relocating production, HP not only mitigates tariff risks but also positions itself to enhance sustainability, diversify supply sources, and strengthen long-term resilience against global market volatility.

However, this transition comes with challenges—balancing cost efficiencies with quality control, managing logistics, and ensuring compliance with new regulatory landscapes. As HP adapts, its experience serves as a blueprint for other tech companies navigating similar headwinds. The shift represents more than a reaction to tariffs; it’s part of a broader strategy to future-proof production and maintain innovation leadership amid global uncertainty.

For deeper insight into how HP’s relocation strategy could influence product pricing and consumer trends, the PCMag report on HP’s tariff response offers valuable analysis. As the industry continues to adjust to trade realignments, the lessons learned from HP’s proactive approach may well shape the next generation of global tech manufacturing.

FAQ – Frequently Asked Questions about HP’s Manufacturing Strategy

What is the main focus of HP’s manufacturing strategy?

The main focus is on adaptability, integration of automation, and sustainability to enhance efficiency.

How does automation benefit HP’s production process?

Automation increases efficiency, reduces costs, and ensures higher quality products through advanced technology.

Why is sustainability important for HP?

Sustainability helps HP reduce waste, lower energy consumption, and create eco-friendly products, which appeals to consumers.

What challenges does HP face when shifting production locations?

HP faces logistics management, workforce adjustments, supply chain disruptions, and compliance with local regulations.